Electronics Ecosystem

The E Ink electronics ecosystem provides customers with a host of design components for quickly designing the electronics and firmware required to integrate an E Ink display into their products. Designers can leverage trained personnel and product ready reference designs to decrease the product time to market.

Touch

E Ink based displays support a variety of solutions for touch. These solutions include several sensor types: resistive, inductive, capacitive or Infrared. Resistive touch responds to pressure applied to the screen and is implemented using patterned electrodes on the display. Inductive touch requires the use of stylus and is implemented with a patterned electrode array behind the display. In capacitive touch, contact creates an increase in capacitance, which is detected by a controller IC. Infrared touch responds to an object, such as a finger, to break the infrared beams over the display to detect interaction with the display.

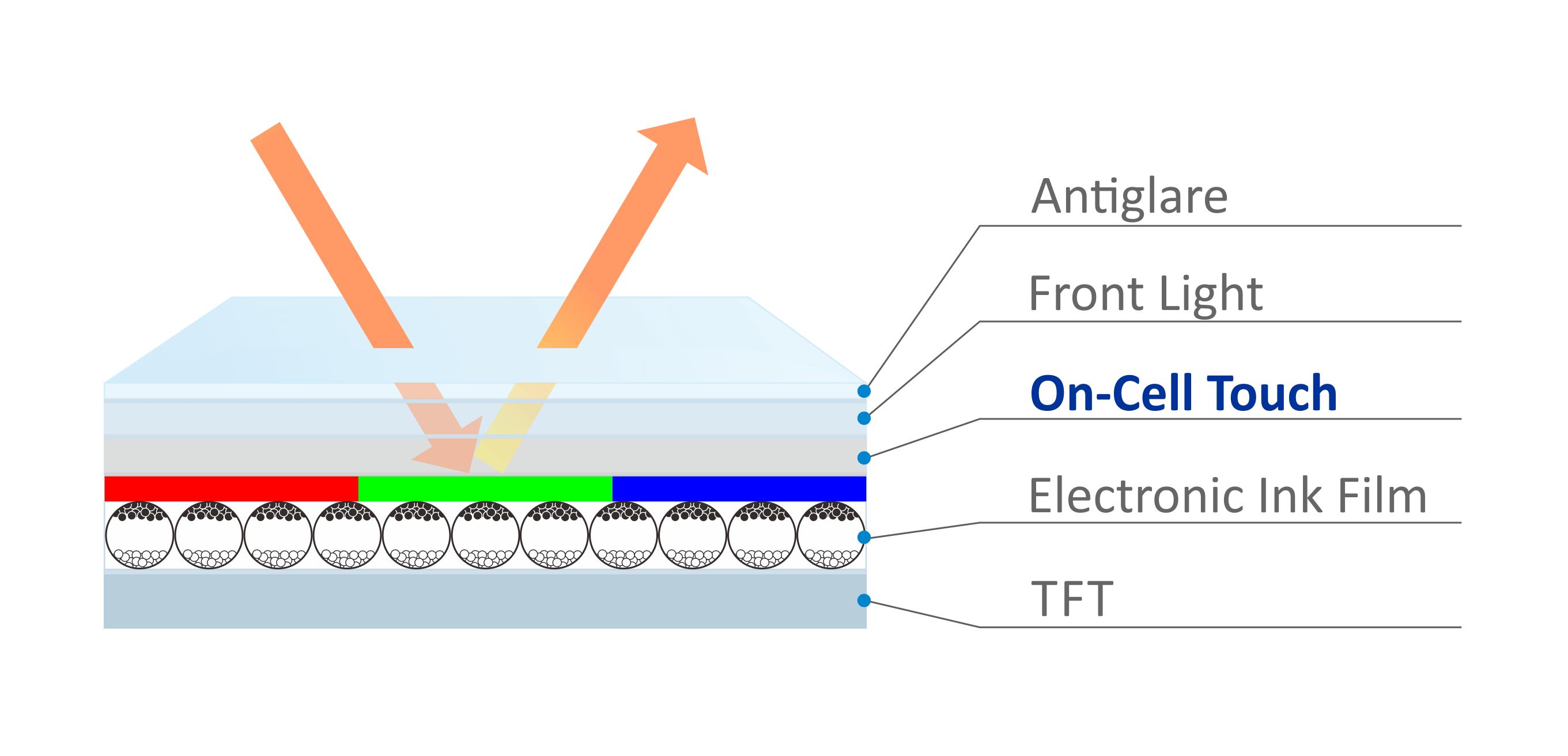

On-Cell Touch ePaper Module

E Ink now offers On-Cell Touch with ePaper modules to provide improved optical performance. This Touch solution provides an increase in the contrast ratio of black and white content of 30%, providing readers with clearer text content. When used in E Ink Kaleido™ Plus, the color contrast ratio is increased by 40% and the color saturation is increased by 15%, providing an enhanced display for color eBook and eTextbook content.

On-Cell Touch ePaper Module Stack

Front Light

E Ink displays can also be in applications with little or no light through the integration of a front light solution. A front light uses a very thin light guide material to uniformly disperse light over the entire display. The light source is usually in the form of LEDs mounted in the sides of the display module. E Ink can manufacture the entire display module including the front light.

Controllers

E Ink displays (also known electrophroetic displays or EPDs for short) require special electronics to control and drive the screen. This design requirement is solved for the designer with the use of an EPD controller. EPD controllers are specialized ICs that have been specifically designed for this task. Because of the complete and simple design solutions they provide, they are one of major reasons for the number of different eReaders that are found on the market today. There are two types of EPD controllers referred to as either Discrete controllers or SoC (System on Chip) controllers. Discrete controller designs consists of dedicated electronics that have all the EPD controls hard wired into the design. SoC controllers are microprocessor based. They usually contain an embedded processor core in the IC and the EPD control functions are implemented through firmware that is developed by the IC supplier.

Power Management

E Ink has partnered with major Semiconductor firms to build integrated power management ICs (PMIC) that are compliant with E Ink voltage requirements for E Ink based displays. PMICs solve the problems of a design needs to support the voltage and power requirements of an EPD display.